- Customer Service TEL:

- +86-18675586197

- Customer Service FAX:

- +86-755-86101451

- Customer Service Email:

- sale@sidiougroup.com

- Online Customer Service:

- +86 18675586197

- sidiougroup

Services

Sample Availability & Policy

Prices are calculated upon receipt of the customer’s detailed requirements. Usually quotation could be provided within 24 hours.

Samples are sent by express, usually via customer’s appointed carrier such as FEDEX, UPS, DHL etc.

Production begins as soon as the customer agrees to our terms, upon sample approval.

Quality Assurance:

Our process includes many quality procedures, in-line and final production.

At our workterm, we are committed to quality requirements of the best standard. We do not sacrifice on quality. We make sure quality is adhered to throughout our operation from sampling to final shipment. We take extra efforts in ensuring the suppliers comply with strict quality control. Quality Assurance is an inherent part of our services and we ensure that our customers do not face any problem at any stage

Quality Control and Inspection Procedures:

We normally follow AQL Level 4.0 inspection method, but on special case we follow any inspection method our customers require. Our quality control and inspection procedure includes the following functions:

1. Our Quality Assurance department checks all the fabric/Accessories to ensure that quality/color etc conforms to the order / style.

2. Our Quality Assurance and merchandising team goes to factory location to evaluate pre-production (size set) sample, patterns, etc to approve for trial production.

3. Quality Assurance team evaluates trial production and then finally approves for bulk production

4. As bulk production starts, our Quality Assurance team goes for inline inspection. This inline inspection during production is performed on daily basis.

5. At the middle stage of production if (standard of quality) result is acceptable / good then we go for pre-final inspection. Here we check the case pack, carton quality, shipping mark, assortment, presentation etc.

6. If the pre-final result is acceptable then we go for final inspection & if it passes, we approve for the final shipment.

About Our R & D Department

Our R&D is undertaken by the Technology Research Department, which consists of the Sample Exhibition Center (SEC), the CAD-Technology Center (CADTC) and the Sample-Working Center (SWC). The SEC displays thousands of samples covering most of our product range. The CADTC is responsible for plate/pattern making, style designing, calculating predicted consumption, graphic processing and photo production. The SWC mainly functions as a sample design and production center.

Product Design

1.Prototype development

2.Research on size

3.Refining manufacturing process

4.Rapid materials estimation

Production Design

1.Processing skill

2.Mass production method

3.Equipment for mass production

4.Aided equipment for mass production

5.Production flow

6.Production arrangement

Artwork Design:

- Artwork for embroidery/printing to be provided by customer.

- Mould charge is not required for new design after order placed.

- Our professional graphic designer can turn your draft for embroidery/printing into beautiful artwork at low cost.

Advantages of technical research and development

To provide multi-product combination, and enhance the competitiveness on creating specified products.

Quotations

Normally your quotation is received within one working days (please note any time difference between countries).

Production Lead-time:

After order confirmation, please allow 15-20 days for print-proof/approval sample. Once confirmed, allow 25-45 days production. Lead times vary depending on seasons, availability of raw materials and components.

Merchandising:

Our merchandising team is committed to complete customer satisfaction. Our merchandising department consists of highly qualified team of merchandisers whose prime aim is to provide full satisfaction to our customer starting from the fabric procurement stage to shipment and reporting the status of the order to the buyers regularly

The services our merchandising team provides to our clients are:

. Systematic follow-up on each stage of production and execution of order on time.

. Monitoring new trends in fabric, fashion and design.

. Locating new reliable sources to meet the requirements of the customer with regard to fashion and design.

. Introducing new samples to buyers to enable them to expand their business.

. Educate the customer about the characteristics of variety of fabrics, dyes, dyeing and printing process, and their positive and negative points and caution the buyers about the pitfalls involved.

. Liaison between the customer and our factories and follow-up.

. Guiding the supplier in preparation of the range to meet the customer's requirements with regard to fashion and design and negotiation.

In addition, we keep our buyers updated at every stage of their orders. Due to this, we prepare daily production report from the manufacturers unit. This report keeps the buyer updated about their order at every stage of the production process.

Guarantees/Warranties/Terms and Conditions

We take full responsibility for any inconformity with buyers' requests in color, quantity, packing and size.

We guarantee the protection of customers’ designs, workmanship, patents and copyrights.

Customized design service is available, executed by professional designers from packaging design majors. Our own designs could be exclusively provided.

Terms could be FOB, CFR, CIF, CIP, DDU, DDP etc.

Logistics Operation Support

Our staff in the Foreign Trade Department are all experienced in the exporting industry.

Being a supply chain service provider, we have the knowledge and expertise to provide total logistic and transportation solutions to our customers. Our qualified personnel work in close association with leading freight forwarders, air and shipping lines at various locations. In addition, we can provide you specific value added services by pre advising all shipments on a regular basis with tentative arrival dates.

- 1 set Form A or Certificate of Origin is provided for each order (for shipment quantity > 1,000pcs & > US$1,500.-)

- The cost of each extra set of Form A is US$70.- and extra set of Certificate of Origin is US$20.-

- Export license (Quota) is required for the States. Its cost is depends on the market fluctuation.

Customers visit our facility

Logistics operation

Q: What is your Corporation stratagem?

A: At beginning, we do OEM for global famous brands. During this period, we continually improve and strengthen us, always following the fashion current of the world and enhance our designing ability gradually. After many years heightening, we are planning to get into the ODM stage. Then, we will co-operate with international brands Operation Company and famous multinational retailing or shop to sell our own brand (D-Star) and Realize our dream (OBM operation in all of the world) P.S.: OBM=Own Brand Manufacturing

Q: What is your output per month?

A: Now we could produce about 300,000 dozen garments.

Q: What is your strength?

A: 1) Under the guaranteed quality and competitive price, we have good reputation and creditability in European and American market. 2) We are a high-tech professional manufactory in the knitting garment..

Q: What are your payment terms?

Normally the following 3 terms of payment are acceptable:

A: 1) Order values less than US$50,000, 40% deposit by T/T (bank transfer), Balance of payment at least 4 days before exit factory or copy of bill of lading by fax or email.

2) Order values more than US$ 50,000, we will accept L/C (Letter of Credit) at sight. All bank charges are at L/C applicant's cost for amount

3) For small order, cash or T/T for full amount in advance.

Q: What are your holidays?

A: We have 3 major holidays.

1) Chinese New Year

This date is different each year and is usually late January or in February for 10-14days, Production and shipping schedules get very tight at this time.

2) Labour Day

May 1 to 7

3) Founding Day Anniversary

October 1 to 7

Ordering Samples

Q: How much for a standard sample?

A: Sample charges apply and are sent on a collect basis. You may also provide us with your freight collect account number with one of the major world-wide express companies (eg.: DHL, UPS, Fedex, TNT, etc.). All expenses are payable prior to a sample being sent.

Regular customers may not be charged except for courier costs.

Q: How much for a 100% correct approved sample WITHOUT placing the order?

A: Sample cost plus Tooling or Setup costs if applicable , plus US$150 handing fee and express charges.

Please note that 100% approved samples are often not possible due to minimum quantities for dying fabrics or materials in your required colour.

Q: How much for an approved sample if I have placed an order?

A: There is no charge if you have placed your order, signed and sent back our Sales confirmation and paid the deposit (if applicable) except for the express charges .

Q: What’s Your Inquiry Details?

A: We do it to your specification. please let us know the followings when you make enquiries:

1. Fabric: Jersey, interlock, rib, honeycomb etc. cotton or cotton mixed (cotton/TC/CVC); carded, semi-combed or combed cotton; and weight usually vary as follows:

a. promotional t-shirts: usual weight 140/150 gsm;

b. Midium weight t-shirts: 160/170 gsm;

c. Heavy weight t-shirts:180/190 gsm;

d. super weight t-shirts: above 200 gsm;

e. light weight t-shirts: 130 gsm to 90 gsm

2. Color: You are suggested to use PANTONE color guide to let us know the exact colors you are aftering; also you can specify color fastness rate or just let us know you need reactive dyeing or directive dyeing;

3. Sizes: specific sizes are desired which will lead to a reasonable quotation;

4. Label or logo requirements: Your artwork can be sent to us by e-mail or CD;

5. Order Quantity: at present moment, we set the min order quantity at 1,000pcs for one color and one size, which we will lower further to cater to more small business;

6. Delivery deadline.

HOW FLASHLIGHT ARE MADE:

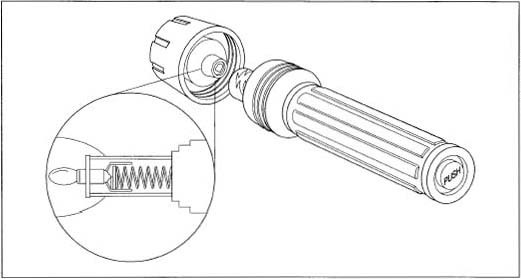

A flashlight is a portable, battery-operated device used for illumination. A typical unit consists of one or more dry cell batteries arranged in a line inside a battery compartment that forms the handle of the light. The flow of electricity from the batteries to the bulb at the front end of the light is controlled through a switch mechanism placed between the batteries and the lamp.

History

Practical, portable light sources have been sought throughout history. Torches and candles were early sources of light but these were largely replaced with lanterns as people learned to burn various animal and mineral oils. However, it was not until the nineteenth century that electricity was harnessed to create light. The modern battery powered flashlight was created in 1898 by Joshua Lionel Cowen, the original owner of the American Eveready Battery Company. Cowen originally developed an idea for a decorative lighting fixture for potted plants. His fixture was composed of a metal tube with a lightbulb and a dry cell battery. Cowen passed his idea to one of his Eveready salespersons, Conrad Hubert, who turned the metal tube, lightbulb, and battery into the world's first flashlight and started selling the batteries and the flashlight. In the last hundred years, advances in technology have resulted in flashlights with hundreds of different styles and features. For example, flashlights are now made with rechargeable batteries that can be used multiple times. Other lights are designed for special operations, such as working underwater or in high-temperature conditions.

Design

The most common flashlight design is the simple household light that consists of a tube-like handle that contains the batteries. This handle is affixed to a threaded head assembly that houses the bulb mechanism. These units operate on standard batteries and provide a typical light output. Special designs are required for industrial or professional use. These lights are made from heavier gauge materials, and are more durable. They are also intended to produce a brighter beam of light. Flashlights with brighter beams are used by the police, firefighters, and the military. Camping lanterns are larger units, usually powered by heavy duty batteries. These frequently use fluorescent tubes as their light source because of their greater energy efficiency, however, this type of bulb does not cast as strong or directed a beam of light. Furthermore, the increased size and weight of this type of lantern limits its portability. Novelty flashlights are designed for use by children. These tend to be made of lightweight plastic and are notable for their visual design. The body of the light may be adorned with decorative plastic overlays that increase the child-appeal of the unit. Their designs are often based on favorite characters from popular cartoons or children's books. Finally, there are a variety of specialty lights designed for particular uses. For example, snake lights, flexible tubes that can be bent or twisted to provide light in hard to reach places. Others are designed to be small enough to fit on a key chain to illuminate keyholes.

Factors to consider when designing flashlights include light output, durability, and the ability to operate in special environments. Battery life is also an important factor, and some lights are designed to be plugged into an electrical outlet to be recharged or to maintain a charge until it is needed. Other lights use special bulbs, like the new generation flashlights built with light-emitting diodes. These are not as bright as conventional incandescent bulbs, but their power consumption is so low that they can last hundreds of hours on a set of conventional batteries, as compared to a few dozen hours for incandescent bulbs.

The Manufacturing Process

Plastic housing

- 1 The plastic components used in flashlight construction are typically injection molded using polystyrene and other durable polymers. In this process, plastic pellets are mixed with plasticizing agents and colorants. This mixture is liquefied by heating and then injected into appropriately shaped molds via an injection plunger. The mold is then subjected to high pressure to assure that the molds are completely filled, and to hold the molds together against force of injected liquid plastics. The end closures are also molded, where usually both internal and external threads are molded. Pressures as high as 2,500 tons may be used for high-speed or multiple-cavity production molders.

- 2 After the injection process, the molten plastic is cooled by forcing water through channels in the mold. The plastic hardens as it cools and the pressure is released. At this point, the two halves of the mold are separated and the plastic part can be removed for finishing. The plastic polymers used in this process are thermoplastic, meaning they can be repeatedly melted so the scrap pieces can be reworked to make additional parts. Therefore, there is very little wasted plastic in this process. Subsequent operations may be required to polish, cut, and finish the plastic parts.

Light source

- 3 Incandescent bulbs are the most common light source used in flashlights. These consist of a metal filament sealed in a glass bulb. When the filament is exposed to an electric current the resistance of the wire causes it to heat up and emit light in the visible wavelengths. The filament is welded to two wires that pass though holes in a cylindrical glass bead that forms the base of the bulb. This structure is placed in a fixture and a cylindrical glass envelope that is closed at one end is placed over the filament. The open end of the glass envelope rests against the glass bead.

-

4 The structure is placed inside a vacuum chamber and heat is applied to seal the glass envelope to the glass bead. The heat causes the glass to soften, and may cause the filament to be displaced to one side. Therefore, care must be taken to ensure the filament is properly aligned or the bulb will not project a beam of light in the right direction.

Other possible light sources include fluorescent bulbs, which are often used in camping lanterns. These bulbs emit light due to the excitation of gas molecules inside the bulb. LEDs, or light emitting diodes, are used in some specialty lights; these emit light when exposed to extremely low levels of electric current. The bulb is often fitted in front of a polished aluminum reflector that helps to focus the light during operation.

Switch and controls

- 5 The electronic circuitry of a flashlight varies depending on its design. Simple lights rely on an off/on switch to make the connection between the wires connecting the battery terminals to the wires extending from the base of the bulb. This type of switch is most commonly a slide type that moves up or down to make the proper connection. The switch assembly is more complicated in the more sophisticated lights. One United States patent describes a flexible metal strip that is depressed to create a contact between the wires.

Assembly

-

6 Depending on the design and the manufacturers capability, units may be assembled on an automated conveyor line or by hand. Some models, particularly those using small watch batteries, have the battery inserted during assembly. Otherwise, the unit may be assembled without the batteries that are inserted later by the consumer. This operation involves screwing the lamp assembly onto the threads on the casing.

A flashlight.

A flashlight.

Packaging

- 7 Assembled units may be placed in some form of outer packaging, such as a clear plastic blister pack or clam shell. The plastic shell may then be attached to a cardboard display card or packed in a box prior to shipping.

Quality Control

Completed flashlights undergo a series of quality control tests to ensure they function properly. First, the bulb must be checked to ensure it is properly aligned with the reflector; if it is misaligned performance may suffer. Second, the switch assembly is evaluated to determine if it makes proper contact with the electrical leads. Third, the seal on the battery compartment must be checked to determine if moisture will not inadvertently enter the battery compartment. This seal must allow venting of gasses that may be formed during battery operation.

The bulb itself must meet separate quality standards. Generally, Division 2-approved flashlights are temperature-rated as TI to T6, where Tl is a temperatures less than, or equal to, 842°F (450°C) and T6 is less than, or equal to, 185°F (85°C). Testing labs used by flashlight manufacturers include Factory Mutual Research Corporation, Underwriters Laboratories, and Demko.

Hazardous environment

Any flashlight that will be used in a hazardous environment or confined space must be properly tested to ascertain that it meets or exceeds all applicable safety standards for those locations. Hazardous Locations are defined by the National Electric Code and include the following classifications. Class I locations are areas where flammable gases may be present in sufficient quantities to produce explosive or flammable mixtures. Class II locations can be described as hazardous because of the presence of combustible dust. Class III locations contain easily ignitable fibers and filings. Hazardous atmospheres are further defined by "groups." These include atmospheres containing acetylene, hydrogen, or gases or vapors of equivalent hazard, such as ethylether vapors, ethylene, cyclo-propane, gasoline, hexane, naptha, benzene, butane, propane, alcohol, acetone, benzol, lacquer solvent vapors, or natural gas. Metal dust, including aluminum, magnesium, and their commercial alloys, may also create hazardous atmospheres. Environments containing carbon black, coal or coke dust, flour, starch, or grain dusts, are classified by the Code. Flashlights designed for use in these environments are individually tested before leaving the factory.

The Future

Manufacturers continue to improve upon the design of their flashlights. New models with improved power sources are becoming increasingly popular. For example, the power plant of a new self-powered flashlight is the revolutionary Freeplay Generator, which is a unique and patented mechanism that stores kinetic energy in a carbon steel spring as the user turns a winding handle. This energy is released as electrical energy when the light is turned on, thus powering the light without any other external power source.

Other improvements in flashlights include tougher polymers for improved durability and smarter computer technology that will allow automatic shut off mechanisms to conserve battery life. Finally, increasingly sophisticated molding techniques will allow the creation of novelty flashlights in a wider variety of shapes and colors.

- Browse By:

- 1Watt LED Flashlight |

- 35W HID Torch Light |

- 3Watt LED Flashlight |

- 50W HID SPOTLIGHT |

- 532nm Green Laser Pointer |

- 5Watt LED Flashlight |

- AA battery flashlight |

- Adapter |

- Adapter Cable |

- aluminum led flashlight |

- Blue Laser pointer |

- cable tester |

- camping lantern |

- Charger |

- Crank Flashlight |

- Cup |

- diving flashlight |

- DV camcorder |

- dynamo flashlight |

- Emergency Lamp |

- Flashlight with Radio |

- focus headlamp |

- Glasses |

- Hand Lamp |

- hand press flashlight |

- Helicopter |

- High Bright LED bicycle light |

- High Performance Flashlights |

- High Power Flashlight |

- Hunting and Shooting Sports |

- Infrared Laser Pointer |

- keyboard |

- Laser Flashlight |

- LED Flashlights |

- LED Headlight |

- LED Keychain light |

- LED lamp |

- LED PEN LIGHT flashlights |

- Luxeon LED Flashlights |

- military flashlight |

- Mini Flashlight |

- Mini Laser Stage Light |

- Multifunction LED Flashlight |

- Multi-Laser Pointer |

- Opener |

- plastic flashlight |

- projector torch |

- promotional flashlight |

- Reading Lamp |

- Rechargeable Flashlights |

- Red Laser Pointer |

- Sidiou Batteries |

- solar flashlight |

- Speaker |

- Spinner |

- stainless steel led flashlight |

- Stand Holder |

- Super Bright LED Flashlight |

- Tactical Flashlight |

- Tester Analyser |

- Trackers |

- USB Fridge |

- UV Flashlight |

- Watch |

- waterproof flashlight |

- Waterproof HID Flashlight |

- webcam |

- Wireless Presenter |

- Work light |

- Yellow Laser Pointer |

- Zoom Flashlight |